RIGGING QUIZ

No. 28

GIVEN:

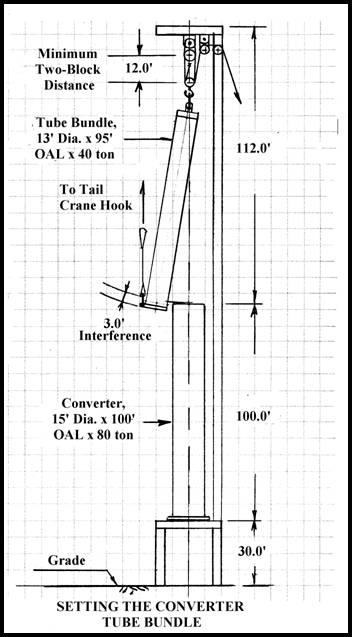

1. A sketch sent from the field to the Rigging Department in the home office of the EPC Contractor, showing an elevation view of a tube bundle being hoisted into place utilizing a three-sided lifting structure with lifting frame for the top and a tail crane for the bottom. Only the rear side of the lifting structure is shown for clarity.

Note that the tube bundle lacks approximately three vertical feet from being hoisted high enough to clear the top of the Converter. This came from field measurements. The field Rigging Superintendent said the tube bundle was hoisted right up to the 12.0’ minimum two-block distance shown on the rigging drawing, which the EPC Rigging Engineer issued. When it wouldn’t clear the top of the Converter, the field took measurements and then laid the tube bundle back on the ground and asked the EPC home office for help in solving the problem.

It would require a 230-ton lift crane to lift the 80-ton Converter on top of the 30’ pedestal and then to lift the 40-ton tube bundle in to place in the Converter, so the client’s requirement was to design, fabricate and install a permanent lifting structure with a lifting frame so that a lift crane would not be needed, just a small tail crane. The refinery is located in a foreign country where large lift cranes are not readily available

The lifting structure with lifting frame was designed and fabricated by the EPC contractor. The Converter fabricator provided the rigging gear.

Note: No blame is assigned at this time for the reason or reasons that caused this problem. That particular part of the problem will be sorted out at a later date.

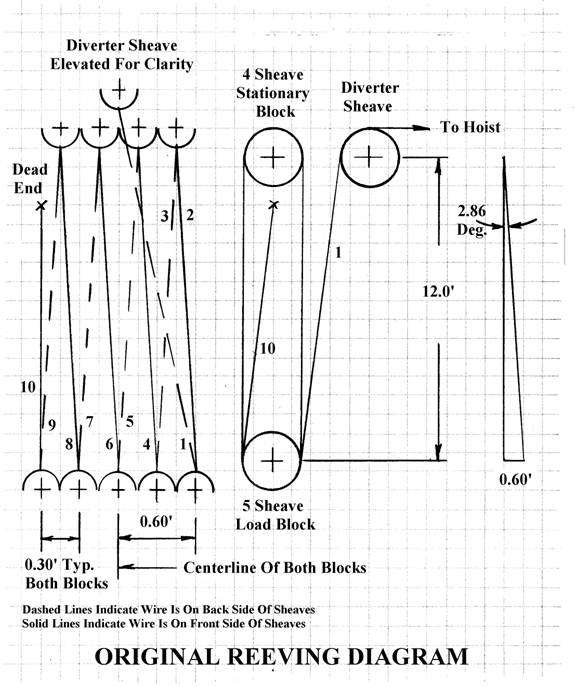

2. A 10 part-reeving diagram for the stationary block and the load block (traveling block) that was provided by the Converter fabricator.

The 2.86 degrees shown above is an industry standard based on a 1:20 fleet ratio.

FIND:

1. Find a permanent solution that will allow the tube bundle to be raised high enough to clear the top of the Converter so that it can be lowered down inside into place.

Any solution should first be based on the erection schedule, as the tube bundle needs to be set in a timely manner. Second, it must be an approved engineered design, as the client needs to know that he can safely use the method for future tube bundle replacements. Third, it should be based on cost.

Maximum Reach Enterprises